The Internet of Things (IoT) generates enormous amounts of sensor data in industrial environments. While traditional machine learning can identify patterns, it often fails to provide the clear mathematical relationships needed for actionable insights.

Symbolic regression addresses this challenge by discovering explicit formulas that connect your IoT sensor data. Unlike neural networks and other black-box models, symbolic regression searches through possible mathematical expressions to find ones that best predict outcomes while remaining interpretable. This makes it particularly valuable for IoT applications where understanding the "why" behind predictions is crucial.

In this article, we'll demonstrate how TuringBot, a desktop application for symbolic regression, can transform raw IoT sensor data into predictive mathematical formulas for equipment maintenance.

Case Study: Predictive Maintenance for Industrial Pumps

Let's tackle a common industrial IoT scenario: predicting pump failures before they occur using vibration sensors.

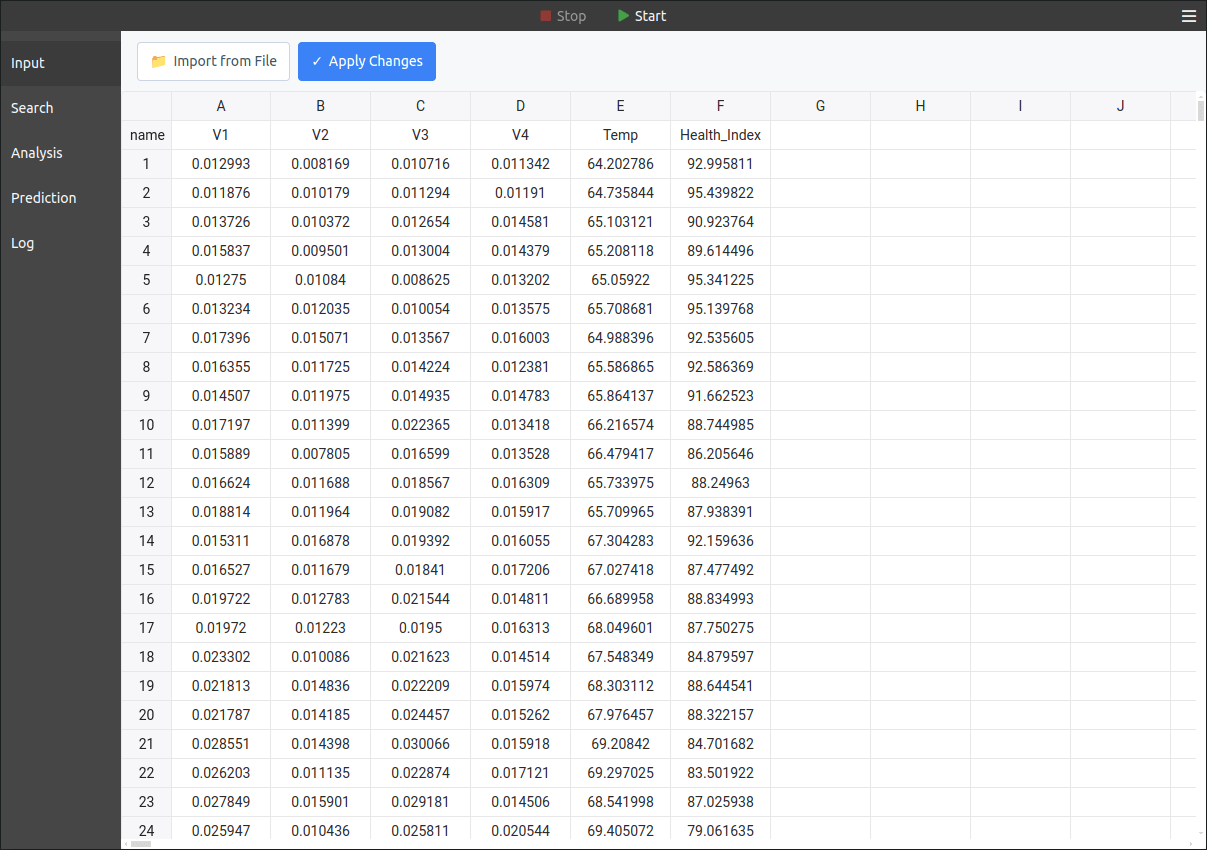

Our dataset contains readings from four vibration sensors (V1, V2, V3, V4) placed at different points on industrial pumps, along with temperature measurements (Temp) and a "Health_Index" that indicates the remaining useful life of each pump.

Step 1: Data Import

After launching TuringBot, we imported our IoT dataset containing sensor readings from multiple pumps at different times, with each row representing a measurement at a specific time:

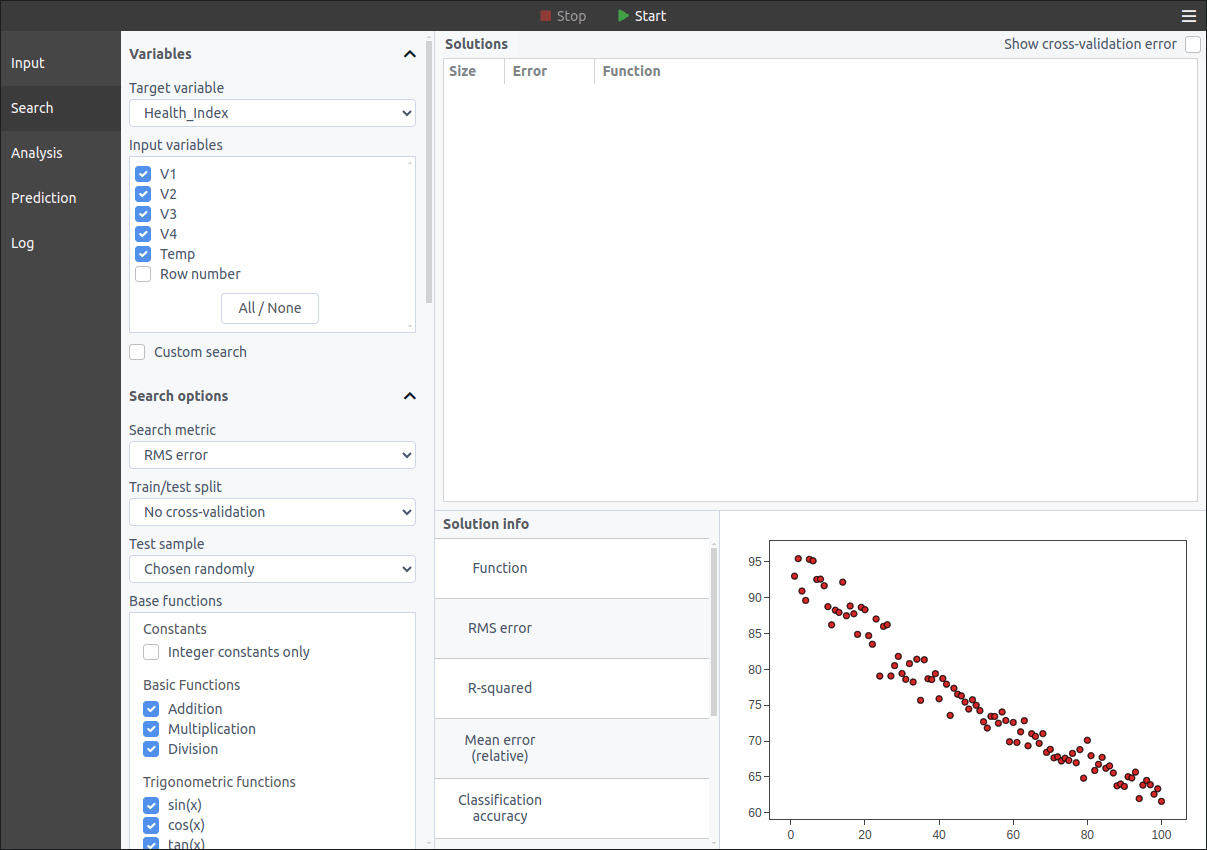

Step 2: Configuration Setup

We configured TuringBot to search for a formula with V1, V2, V3, V4, and Temp as inputs and Health_Index as output, using RMSE as the error metric. We enabled all mathematical operators including logarithmic functions, which are often useful for analyzing vibration patterns:

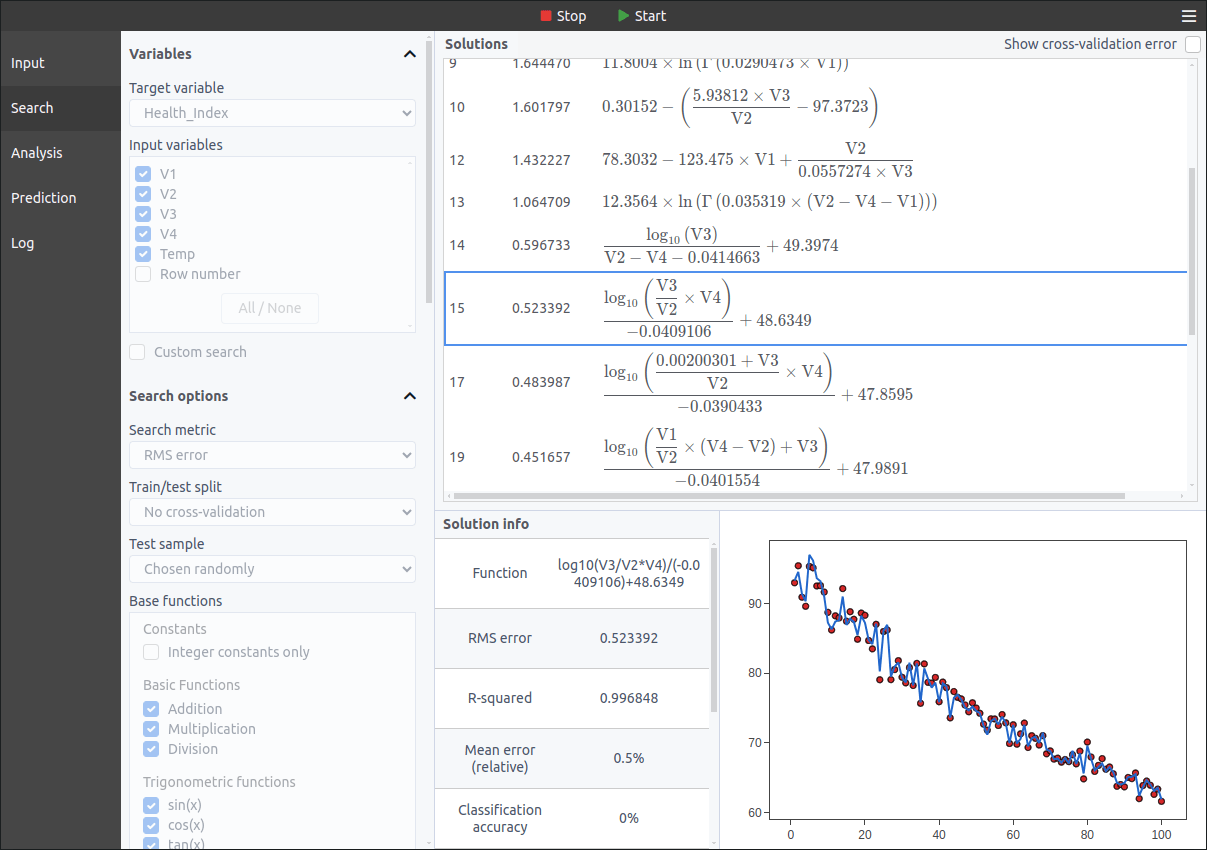

Step 3: Running the Search and Results

After running for approximately 10 minutes, TuringBot discovered this remarkably simple yet powerful formula, which was chosen because larger formulas presented diminishing returns:

Health_Index = 0.523392 × log10(V3/V2 × V4)/-0.0409106 + 48.6349With an RMSE of 0.52, this formula achieved excellent prediction accuracy. Here are all the formulas that were discovered:

Insights from the Formula

This formula provides key insights about pump health:

- The ratio of V3 to V2 multiplied by V4 captures critical vibration relationships between different measurement points

- The logarithmic relationship reveals that combined vibration effects follow a non-linear progression typical of accelerating mechanical wear

Most importantly, this formula reveals that it's not the absolute vibration values that matter most, but rather the relationships between measurements from different sensor positions—information that would be difficult to extract through simple visualization or correlation analysis.

Additional IoT Analytics Applications

While our example focused on vibration sensors for pumps, symbolic regression with TuringBot is equally applicable to other IoT domains:

- Smart buildings can discover formulas linking multiple environmental sensors to energy consumption, enabling precise HVAC optimization

- Smart agriculture applications can find relationships between soil moisture, temperature, and crop yield to optimize irrigation schedules

- Battery-powered IoT networks can develop formulas to predict device longevity based on transmission patterns and environmental conditions

Technical Advantages

The formula discovered by TuringBot offers specific benefits for IoT implementations:

- Edge computing compatibility: The simple formula can run on resource-constrained IoT edge devices, allowing for real-time health monitoring without constant cloud connectivity

- Explainability: Maintenance teams can understand exactly which sensor relationships are contributing to declining health indices

- Data efficiency: Once the formula is deployed, only the necessary sensor data needs to be transmitted, reducing bandwidth requirements in IoT networks

Conclusion

Symbolic regression with TuringBot transforms IoT vibration data into actionable maintenance insights. By extracting the exact mathematical relationship Health_Index = 0.523392 × log10(V3/V2 × V4)/-0.0409106 + 48.6349, we've solved a real predictive maintenance problem with a formula that's immediately deployable, physically meaningful, and runs efficiently on edge devices.

This approach bridges the gap between data collection and decision-making in IoT environments, producing mathematical formulas that not only predict outcomes but explain the underlying physical relationships driving those predictions.